FELLA Maschinenbau GmbH

Tradition and innovation for 70 years

Our values - Flexibility, competence and reliability as key factors for high customer satisfaction

As a medium-sized, innovative family company FELLA stands for flexible solutions and quality-conscious production. Furthermore we represent a reliable partner for our customers and suppliers. A high customer satisfaction underlines the competence of our company in machinery and plant engineering, building of hydropower stations and in the manufacturing and machining of big parts.

In future we also want to contribute to global energy transformation through our engagement in renewable energies. In addition to that we want to offer flexible and reliable support as well as highest manufacturing quality from a single source further on to our customers from electrical, textile, food and chemical industry.

Our philosophy - Mechanical engineering as engine of our economy

Mechanical engineering today is one of the most important pillars of our domestic economy. Germany with its mechanical engineering products has proved a recipe for robustness, reliability, quality and innovation all around the globe.

As a traditional, medium-sized company we are fully aware of this special responsibility. For us it is self-evident, that only through highest processing quality, precision, best materials and continuous development and innovation we can act as a driving force in this environment.

Thus we break the mould with our own developments in order to approach upcoming challenges, steadily increasing because of national and international competition, and finally to ensure this site for future generations.

Our mission - Preserving roots and shaping future

Founded as a simple repair shop in 1949 our company has evolved to a modern manufacturing site in machinery and plant engineering and a renowned supplier for industry. The excellent manufacturing quality, the know-how gained over several decades, steady expansion and purposeful investment opened the doors to new business segments and own innovations.

Thus the increasing importance of renewable energies has led to the development of own products in cooperation with regional partners. Beyond the FELLAMOVER, a 2-axis location optimized repositioning system for photovoltaic panels, FELLA has created the DIVE-turbine, an efficient and distinctly fish-friendly small hydropower turbine, which therefore even received the Bavarian environmental award in 2009.

Our team - Qualified and motivated employees as the most valuable asset

In our team with around 50 employees we have all sorts of professional groups that are responsible for planning, engineering, manufacturing and selling of components and machines - from CNC specialists and qualified welding and assembly personal through to business people, engineers, technicians and technical product designers.

In a cooperation based on partnership and flat hierarchies we strive to foster the engagement of every single employee through appropriate measures and to ensure and improve producution and quality of our products as a result. With our training places on offer we account for the demographic change and take care of our ability to approach future challenges with a capable, well harmonising and motivated team.

References

We deliver custom-made components, assemblies and machines of highest quality:

Production and assembly of hydropower stations starting with single parts right up to ready-to-mount turbine

Processing and balancing of rotationally symmetric and voluminous parts

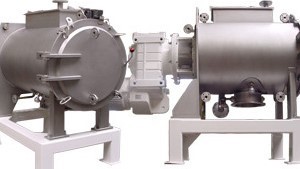

Double-walled, liquid-cooled devices for food industry and process technology

Complex welding, turning and milling operations geared to customer needs

Electromotors made out of thick-walled steel tubes with wall thickness up to 60 mm, also with liquid-cooled outer jacket

Development and implementation of customer specific production and assembly solutions

Manufacturing of complex, modular-build composite constructions combining cast and welded parts